You require dependable janitorial cleaning in Brampton that's founded on documented SOPs aligned to WHMIS/CSA, daily QA inspections with scored checklists, and timestamped task logs. Look for DIN-registered disinfectants with verified dwell times, color-coded microfiber, HEPA filtration, and calibrated equipment. Companies should satisfy OHSA and Peel Region requirements, ensure SDS access, and track KPIs like complaint rate, rework, and response time. Tailored plans, buffer-stocked supplies, and supervisor verification maintain sites audit-ready and spotless—learn how these controls convert to measurable results.

Important Highlights

- Documented SOPs compliant with WHMIS/CSA, calibrated tools, and color-coded systems ensure safe, consistent cleaning across Brampton facilities.

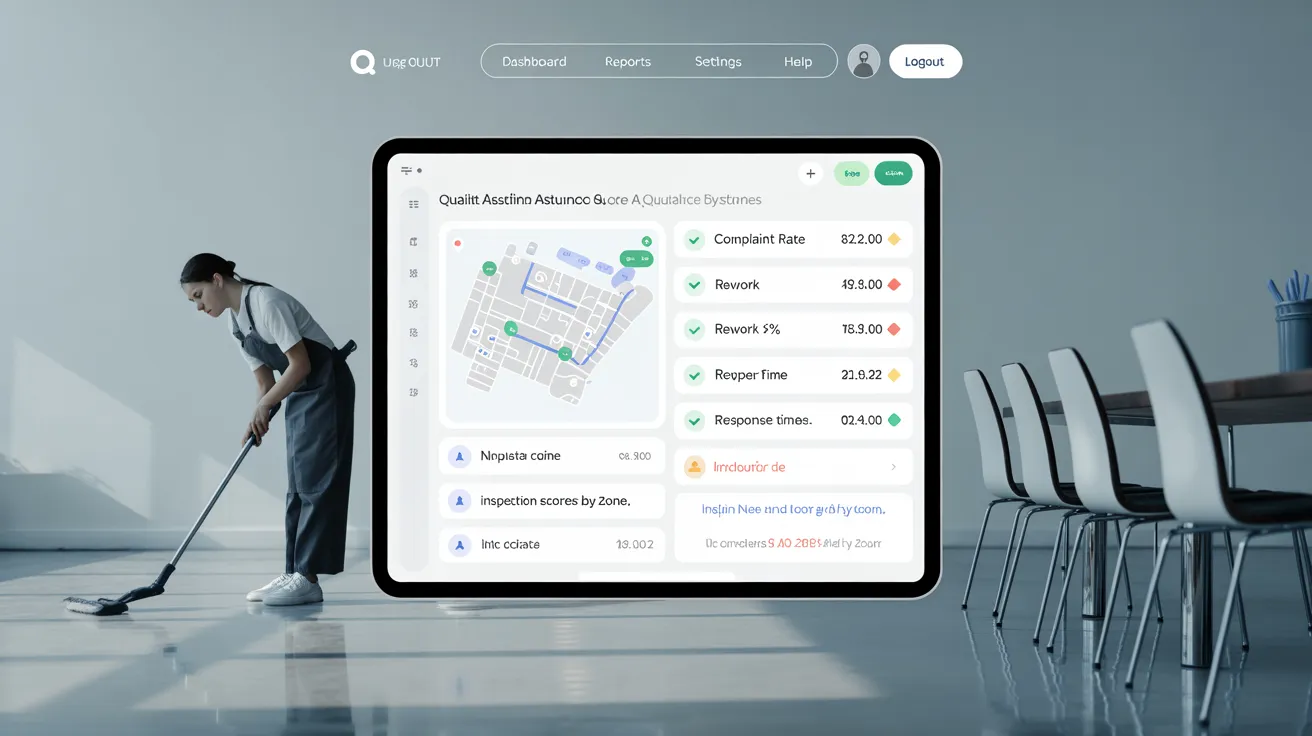

- Systematic QA inspections with scored checklists, timestamped logs, and KPI dashboards stop service drift and offer transparent performance.

- Site-specific plans map responsibilities, dwell times, surface care routines, and equipment to every location's risk profile and traffic patterns.

- Compliance-driven operations: alignment with OHSA and Peel public health, access to SDS, properly labeled containers, regular audits, and incident and corrective-action documentation ready for inspections.

- Qualified staff, endorsed with manager oversight, uniform SKUs and buffer stock, and scheduled maintenance reduce downtime and supply stockouts.

What Defines Janitorial Cleaning Reliable" in Brampton

While cleaning companies may pledge spotless surfaces, dependability in Brampton's janitorial cleaning appears in documented frameworks and dependable deliverables. You can demand documented SOPs aligned to WHMIS along with CSA, routine QA inspections with scored checklists, and timestamped logs for task completion. Reliable teams use consistent staffing, so you're not retraining crews or losing site knowledge. Supervisors verify touchpoint sanitation frequency, floor-care cycles, and restroom uptime against SLAs.

You also must have dependable inventory: uniform SKUs, buffer stock, and consumption tracking to avert stockouts of liner products, microfiber, and EPA-registered chemical products. Well-calibrated equipment, coded tools, and upkeep schedules lower cross-contamination and downtime. Visible incident reporting, remediation timelines, and KPI dashboards-customer complaint rate, rework rate, and turnaround time-establish control. This is how you ensure reliable cleanliness and minimized risk.

Primary Services Every Brampton Business Should Look For

You should expect daily office cleaning that covers frequently-touched disinfection, waste removal, and workstation reset to preserve uptime and brand standards. Restroom sanitation must meet health-code benchmarks with EPA-registered chemicals, verified contact times, and documented inspections. Floor care programs must outline strip-and-wax cycles, scrub-and-recoat intervals, and carpet extraction schedules customized for your traffic patterns and finishes.

Daily Office Cleaning

Conducted regularly with attention to detail, daily office cleaning keeps Brampton workplaces productive, regulation-compliant, and polished. You receive high-touch surface disinfection, streak-free windows, and vacuumed traffic lanes that reduce dust and allergens. Crews manage workstation decluttering, empty bins, and align chairs to restore order before doors open. They address spills immediately, sanitize shared touchpoints, and reset the reception area so first impressions make an impact.

We implement microfiber color-coding, HEPA filtration, and eco-certified cleaning products to adhere to local standards and protect finishes. Work surfaces, keyboards, and telephones get strategic wipe-downs that minimize cross-contamination without compromising equipment. End-of-day touchups manage late-day messes, ensuring your team starts fresh every morning. Checklists ensure scope: lobby dusting, boardroom resets, kitchen surface cleaning, and supply checks. The outcome: fewer complaints, stronger brand image, and consistent uptime.

Bathroom Sanitation Requirements

Regularly maintained restrooms anchor your Brampton facility's hygiene program and compliance. You need a written sanitation schedule that targets high-touch points—toilet handles, taps, soap dispensers, door locks—every service visit. Technicians should use hospital-grade, DIN-registered disinfectants with correct dwell times and color-coded microfiber to avoid cross-contamination. Restroom odor control isn't just air freshening; it's source removal: enzymatic read more drain treatments, urinal screen rotation, grout restoration, vent cleaning, and sealed trash liners.

Every detail counts. Check fixture descaling, mirror and stainless polishing, and dispenser calibration to reduce waste. Include stall partition maintenance: degrease, disinfect hinges and brackets, repair delamination, and touch up or swap out panels to maintain a clean, polished look. Mandate ATP or fluorescent marker audits, signed checklists, and incident logs. The end result: healthier occupants, fewer complaints, and measurable cleanliness.

Flooring Care Services

Although floor care may seem simple, an effective Brampton program is a systematic system: routine sweeping and HEPA vacuuming, mechanical scrubbing with neutral or enzymatic cleaners appropriate for substrate, and scheduled restorative work such as scrub-and-recoat, strip-and-finish, or diamond polishing for natural stone and concrete. You'll get measurable results by pairing chemistry, pads, and dwell times with each surface. For VCT, we watch finish film build, burnish to target gloss, and schedule recoat cycles by traffic counts. For porcelain, ceramic, and natural stone, tile maintenance includes agitation with cylindrical brushes, precision grout restoration, and sealed protection to minimize resoiling. On LVT, we eliminate acrylic finishes and use polyurethane-compatible cleaners. We track slip resistance, ATP readings, and gloss levels, so your floors stay consistent, last longer, and comply with safety standards.

The Value of Consistent Quality Control

When quality control follows a set cadence-daily inspections, documented checklists, and measurable KPIs-you stop service drift, protect your facility assets, and lower corrective costs. You also regulate outcomes across shifts and sites, so restroom hygiene, touchpoint disinfection, and waste handling stay consistent during peak use.

Use quality audits to verify SOPs, confirm dilution ratios, and ensure equipment maintenance logs. Connect findings to corrective actions with deadlines and photo verification. Record trend data by zone-lobbies, production areas, and back-of-house to determine root causes, not symptoms. Close the loop with client feedback to verify that visual standards, odor control, and uptime meet expectations.

This discipline maintains finishes, lengthens machine lifecycles, and decreases rework. Ultimately, steady oversight drives safer environments, predictable budgets, and improved occupant satisfaction.

How to Evaluate and Select a Reliable Provider

Before committing to any contract, build a short list using objective criteria: demonstrated sector experience in Brampton, WSIB clearance and liability coverage, documented SOPs aligned to ISSA/OS1 or GBAC standards, and a track record of meeting KPIs comparable to yours. Check supervisor-to-cleaner ratios, training schedule, and chemical/equipment inventories. Obtain data: inspection scores, rework rates, incident logs, and response times.

Meet with operations leaders, not just sales. Request site-specific references and examine client feedback for service consistency, not just star ratings. Complete a compliance check: WHMIS training, police checks, and supply chain transparency. Insist on measurable SLAs with escalation paths. Examine contract terms-scope, frequencies, exclusions, consumables, price-adjustment triggers, and termination rights. Test the service with a defined acceptance test before granting the full term.

Tailored Cleaning Plans for Different Facilities

Initiate the process by identifying each facility's risk profile and operational pace, then transform that into a scope-by-space plan. You'll establish cleaning frequencies, acceptable downtime, access protocols, and material sensitivities for each area-lobbies, production floors, classrooms, exam rooms, and kitchens. Construct task lists that specify methods, dwell times, and sector specialized equipment: autoscrubbers for warehouses, HEPA uprights for offices, microfiber systems for clinics, low-moisture extraction for carpeted suites.

For offices, prioritize touchpoint cycling, meeting-room resets, and post-tenant improvements turnover cleans. In retail, synchronize overnight detail work with merchandising schedules and slip-resistant floor care. In industrial sites, contain degreasing, capture particulates, and sequence equipment wipe-downs by shift. For schools, synchronize deep cleans with breaks. Assess results with ATP spot checks, rework logs, and service-level scorecards.

Health, Safety, and Compliance Standards

You demand janitorial work in Brampton to comply with municipal bylaws, provincial health codes, and WSIB/WHMIS requirements without exceptions. This ensures you obtain documented SOPs, safe chemical handling, PPE usage, and incident reporting conforming to Ontario regulations. You also obtain certified staff educated in WHMIS, infection control, bloodborne pathogen protocols, and site-specific hazard assessments to minimize risk and preserve audit readiness.

Conformity With Local Regulations

Although pristine floors matter, regulatory compliance in Brampton is essential: your janitorial program must align with Ontario's Occupational Health and Safety Act (OHSA), WHMIS 2015 (GHS), and Peel Region public health guidelines. You must record chemical inventories, maintain SDS accessibility within constant access, and label secondary containers per GHS. Conduct internal audits that validate bylaw compliance, confirm wastewater disposal protocols, and log hand‑wash and disinfection frequencies in high‑risk zones. Monitor permit updates affecting biomedical, food‑service, or childcare environments, and ensure vendor products carry DIN or PCP numbers where required.

Implement color‑coded tools to stop cross‑contamination, place hazard signage in compliance with ANSI/CSA, and calibrate disinfectant dwell times against manufacturer specifications. Retain incident logs, corrective actions, and inspection reports ready for unannounced visits, decreasing citations and insurance exposure.

Accredited Workforce Preparation

Since compliance is only as effective as the individuals executing it, create a certified training program that maps each role to OSHA, WHMIS 2015 (GHS), and Peel public health requirements, then assesses competency with documented assessments. Train supervisors along with frontline personnel on hazard communication, SDS interpretation, disinfectant dwell times, dilution control, and color-coded tools. Require practical demonstrations for biohazard cleanup, ladder use, lockout/tagout, and sharps response.

Formalize onboarding with role-specific modules, then schedule regular assessments every quarter to validate retention and correct drift. Deploy mentorship programs to pair experienced leads with new hires, reinforcing hand hygiene practices, spill containment, and site logs. Track credentials, incident trends, and corrective actions in a protected LMS. Audit sites regularly, retrain right away after gaps, and connect credentials to shift eligibility.

Environmentally Conscious Products and Sustainable Methods

When sustainability directs your janitorial program in Brampton, you reduce chemical load, protect occupant health, and reduce lifecycle costs without sacrificing cleanliness. You mandate third-party green certification for chemicals, paper, liners, and equipment, securing documented VOC limits, biodegradability, and end-of-life recoverability. You utilize concentrated chemistries with closed-loop dilution and refill systems to reduce plastic, shipping weight, and dosing errors. You establish microfiber, color-coding, and high-filtration vacuums to capture fine particulates and increase surface life. You move to CRI/Green Label equipment, auto-scrubbers with smart dosing, and cold-water technologies to limit energy use. You confirm outcomes with ATP testing, indoor air quality readings, and product usage dashboards. You also educate crews on proper dwell times and disposal, then assess compliance monthly.

Scheduling That Reduces Workplace Interruptions

Sustainability establishes the benchmark; now synchronize cleaning schedules to keep Brampton workplaces efficient while floors, restrooms, and touchpoints stay consistently hygienic. You'll minimize downtime by mapping service windows to operational peaks, traffic flows, and noise tolerances. Use off-hours shifts for machine scrubbing, high-speed burnishing, and washroom deep cleans; reserve day-porting for spill response, supply checks, and discreet disinfection.

Build a cadence: day-to-day wipe-downs, twice-weekly high-touch sanitizing, and monthly detail tasks. Use staggered starts so crews sequence zones-entryways, meeting rooms, production areas-without blocking access or interrupting meetings. Create uniform job cards, color-coded tools, and route times to verify completion and minimize dwell. Track KPIs: complaint rates, response times, ATP scores, and slip incidents. With structured scheduling, you can sustain cleanliness, safeguard productivity, and manage costs.

Why Regional Experience Brings Better Results in Brampton

Even though national providers guarantee scale, Brampton-native teams yield stronger performance because they understand the city's building stock, bylaws, and business rhythms. You enjoy regional knowledge that results in compliant waste handling, correct chemical selections for existing masonry and new LEED surfaces, and workflows aligned to Peel Region regulations. Local supervisors expect rush-hour access limits, condo board specifications, and plaza loading dock windows, so crews appear equipped and on time.

Seasonal modifications are exact: salt buildup extraction methods in winter, pollen extraction and HVAC coil care in spring, dampness-induced mold prevention in summer, and leaf-entry control in fall. Professionals understand which corridors collect debris and which facilities require daytime touch-ups. This expertise cuts down on rework, preserves finishes, improves indoor air quality, and ensures your operations continue without disruption.

Frequently Asked Questions

Do You Provide Emergency Cleanup for Water Damage or Unexpected Situations?

Emergency cleanup services are available 24/7. We activate a round-the-clock response team, stabilize the location, execute rapid water extraction, and stabilize affected areas. Technicians assess moisture, remove unsalvageable materials, and apply antimicrobial agents for mold prevention. We log damage, photograph damaged sections, and coordinate insurance claims to speed up approvals. You'll get clear timelines, drying reports, and daily updates. We wrap up with odor control and verification readings to make certain safe, compliant reentry.

Are Staff Able to Offer After-Event or Post-Construction Cleaning Services?

Absolutely-our trained staff takes care of post event and post-construction cleaning. Operating seamlessly, we eliminate dust and debris extraction, HEPA-vacuum surfaces, and execute deep sanitation on restrooms, touchpoints, and high-traffic zones. We meticulously clean fixtures, polish floors, and remove adhesive, paint splatter, and haze. We bag up waste, reset spaces, and stage for reoccupancy. You'll get a documented checklist and a final walkthrough to ensure scope, cleanliness levels, and readiness before handoff.

What Happens To Lost-And-Found Items During The Cleaning Process?

You process lost-and-found items through a formalized chain of custody. Your cleaners discover discovered property during sweeps, tag and bag it, then complete item documentation with time, location, and cleaner ID. You document the item photographically, seal it, and secure it in a locked bin. You alert the site contact within one hour, record resolution, and require signed release confirmation. You audit logs weekly and purge per client policy after the retention window.

Do Cleaning Personnel Have Training to Work Around Sensitive Equipment or Servers?

Specifically, you get cleaners equipped to work around sensitive equipment and servers. You receive strict security protocols, background-checked staff, and badge-controlled access. You see industry-grade equipment handling: ESD-safe tools, anti-static attire, cable-conscious routing, and no-touch zones. You receive server-room SOPs-sealed vacuums, particulate controls, humidity checks, and scheduled maintenance windows. You gain documented checklists, chain-of-custody logs, and supervisor sign-offs, maintaining uptime, safeguarding data integrity, and minimizing risk during every cleaning cycle.

How Fast Do We Address Service Issues or Re-Clean Requests?

You will get a priority response within hours, with same day turnaround for critical service matters or re-clean requests. We sort tickets by site criticality and SLA, dispatch a supervisor, and document corrective actions. For non-urgent items, we guarantee next-business-day resolution. You will get scheduled callbacks to verify customer satisfaction and sign-off. We record response KPIs, technician arrival windows, and re-clean outcomes to ensure measurable results and continuous service improvement.

Final Thoughts

When you secure the building, it's by design the lobby gleams, touchpoints are sanitized, and waste streams are sorted-because your janitorial program relies on verified checklists, ATP testing, WSIB-compliant training, and eco-certified chemistries. You've assessed vendors, created site-specific SOPs, and scheduled unobtrusive night shifts, so uptime remains high and complaints remain low. With Brampton-specific codes, seasonal salt control, and LEED-aligned practices, you don't expect reliable cleaning-you monitor it, audit it, and observe it every morning.